Phosphor Wheel Manufacturing for Laser Projection Systems in 2025: Unveiling Market Growth, Technological Breakthroughs, and the Road Ahead. Discover How Next-Gen Materials and Precision Engineering Are Shaping the Future of Laser Displays.

- Executive Summary: Key Findings and 2025 Highlights

- Market Overview: Size, Segmentation, and 2025–2030 Growth Forecasts

- Growth Drivers and Restraints: What’s Powering the Phosphor Wheel Boom?

- Competitive Landscape: Leading Manufacturers and Emerging Players

- Technological Innovations: Materials, Coatings, and Manufacturing Advances

- Application Trends: Laser Projection in Cinema, Automotive, and Industrial Sectors

- Regional Analysis: Asia-Pacific, North America, Europe, and Rest of World

- Market Forecasts: CAGR, Revenue Projections, and Volume Estimates (2025–2030)

- Challenges and Risk Factors: Supply Chain, IP, and Regulatory Hurdles

- Future Outlook: Disruptive Technologies and Strategic Opportunities

- Appendix: Methodology, Data Sources, and Glossary

- Sources & References

Executive Summary: Key Findings and 2025 Highlights

The phosphor wheel manufacturing sector for laser projection systems is poised for significant advancements in 2025, driven by surging demand in cinema, large venue, and automotive headlight applications. Key findings indicate that manufacturers are prioritizing higher thermal stability, improved luminous efficiency, and longer operational lifespans to meet the evolving requirements of next-generation laser projectors. The integration of advanced ceramic and composite materials is enabling phosphor wheels to withstand higher laser power densities, reducing degradation and color shift over time.

A notable trend is the increasing adoption of automated precision manufacturing processes, such as laser cutting and robotic assembly, which are enhancing yield rates and consistency across production batches. Leading suppliers are also investing in proprietary phosphor formulations and innovative wheel geometries to optimize color rendering and brightness, addressing the needs of both DLP and LCD-based projection systems. In 2025, the market is witnessing a shift toward eco-friendly manufacturing practices, with several companies implementing waste reduction and recycling initiatives in line with global sustainability goals.

Strategic partnerships between phosphor material producers and projection system OEMs are accelerating the pace of innovation, resulting in customized solutions tailored for specific end-use scenarios. For instance, the automotive sector’s demand for compact, high-brightness laser headlights is prompting the development of miniaturized, high-durability phosphor wheels. Meanwhile, the cinema and large venue segments are driving the scale-up of high-output wheels capable of supporting ultra-high-definition and HDR content.

Looking ahead to 2025, the competitive landscape is expected to intensify, with established players such as OSRAM GmbH, Nichia Corporation, and Philips expanding their product portfolios and production capacities. Regional manufacturing hubs in East Asia, particularly in China and Japan, are set to play a pivotal role in global supply chains, leveraging advanced R&D capabilities and cost efficiencies. Overall, the phosphor wheel manufacturing industry is entering a phase of robust growth and technological refinement, positioning itself as a critical enabler of the next wave of laser projection innovation.

Market Overview: Size, Segmentation, and 2025–2030 Growth Forecasts

The global market for phosphor wheel manufacturing, specifically for laser projection systems, is experiencing robust growth driven by the expanding adoption of laser-based display technologies in sectors such as cinema, education, automotive, and large-venue entertainment. Phosphor wheels are critical components in laser projection systems, converting blue laser light into broad-spectrum white or colored light, thereby enabling high-brightness and high-efficiency projection.

In 2025, the market size for phosphor wheel manufacturing is estimated to reach approximately USD 350–400 million, with Asia-Pacific leading production and consumption due to the presence of major electronics and display manufacturers. Key market segments include material type (ceramic vs. glass-based phosphor wheels), application (cinema projectors, automotive head-up displays, large venue projectors, and home entertainment), and end-user industries. The cinema and large-venue segments account for the largest share, propelled by the ongoing transition from lamp-based to laser-based projection systems.

Segmentation by material type reveals a growing preference for ceramic phosphor wheels, which offer superior thermal stability and luminous efficiency compared to traditional glass-based alternatives. This trend is particularly pronounced in high-brightness applications, where performance and longevity are critical. Leading manufacturers such as OSRAM GmbH and Nichia Corporation are investing in advanced phosphor formulations and wheel designs to meet evolving industry requirements.

From 2025 to 2030, the phosphor wheel manufacturing market is projected to grow at a compound annual growth rate (CAGR) of 8–10%. This growth is underpinned by increasing investments in laser projection infrastructure, particularly in emerging markets, and the proliferation of 4K and 8K display technologies. Additionally, the automotive sector is expected to be a significant growth driver, as laser-based head-up displays and adaptive lighting systems become more prevalent in next-generation vehicles.

Regional analysis indicates that while Asia-Pacific remains the manufacturing hub, North America and Europe are witnessing increased demand for high-performance phosphor wheels, driven by technological advancements and stringent quality standards. Strategic collaborations between projector OEMs and phosphor wheel suppliers, such as those involving Panasonic Corporation and Barco NV, are further shaping the competitive landscape.

Growth Drivers and Restraints: What’s Powering the Phosphor Wheel Boom?

The rapid expansion of the laser projection market is fueling significant growth in phosphor wheel manufacturing. One of the primary drivers is the increasing adoption of laser-based projection systems in cinemas, large venues, and educational institutions, where high brightness, color accuracy, and energy efficiency are paramount. Laser projectors, leveraging phosphor wheels, offer longer lifespans and lower maintenance compared to traditional lamp-based systems, making them attractive for commercial and professional applications. The shift towards 4K and even 8K resolution content further necessitates advanced phosphor wheel technologies capable of delivering superior color rendering and brightness.

Technological advancements in phosphor materials and wheel design are also propelling the market. Innovations such as improved thermal management, higher quantum efficiency, and the use of robust ceramic phosphors have enabled manufacturers to produce wheels that withstand intense laser irradiation while maintaining consistent performance. Companies like OSRAM GmbH and Nichia Corporation are at the forefront, investing in R&D to enhance phosphor conversion efficiency and durability, which directly benefits projector manufacturers seeking reliable, high-performance components.

On the demand side, the proliferation of immersive display technologies in entertainment, simulation, and digital signage is expanding the addressable market for laser projectors and, by extension, phosphor wheels. The growing popularity of large-format displays in public spaces and the increasing use of projection mapping for events and advertising are further boosting demand. Additionally, the global push for energy-efficient and environmentally friendly technologies aligns with the advantages offered by laser phosphor projection, supporting broader adoption.

However, the market faces notable restraints. The high initial cost of laser projection systems, partly due to the complexity and precision required in phosphor wheel manufacturing, can deter price-sensitive customers. Manufacturing challenges, such as ensuring uniform phosphor coating, precise wheel balancing, and effective heat dissipation, require significant investment in specialized equipment and quality control. Furthermore, the availability of high-quality raw materials and the need to comply with stringent environmental and safety regulations can impact production costs and timelines. Despite these challenges, ongoing innovation and economies of scale are expected to gradually mitigate these barriers, sustaining the phosphor wheel boom in the coming years.

Competitive Landscape: Leading Manufacturers and Emerging Players

The competitive landscape of phosphor wheel manufacturing for laser projection systems in 2025 is characterized by a blend of established industry leaders and innovative emerging players. Phosphor wheels are critical components in laser projection, converting blue or near-UV laser light into broad-spectrum white light, which is essential for high-brightness, color-accurate projection in applications ranging from cinema to automotive head-up displays.

Among the leading manufacturers, OSRAM GmbH continues to hold a significant market share, leveraging its expertise in phosphor materials and precision engineering. The company’s focus on high thermal stability and long operational lifespans has made its phosphor wheels a preferred choice for high-end projection systems. Similarly, Philips maintains a strong presence, particularly in the development of custom phosphor formulations and advanced wheel designs that enhance color rendering and efficiency.

Asian manufacturers, notably Nichia Corporation and Seoul Semiconductor Co., Ltd., have expanded their influence by integrating proprietary phosphor technologies and cost-effective manufacturing processes. These companies are recognized for their rapid innovation cycles and ability to scale production to meet the growing demand from the consumer electronics and automotive sectors.

Emerging players are also making notable strides, particularly in China and Taiwan, where companies such as Guangdong Nationstar Optoelectronics Co., Ltd. are investing in research and development to improve phosphor conversion efficiency and thermal management. These firms often collaborate with local universities and research institutes, accelerating the commercialization of novel phosphor materials and wheel architectures.

The competitive environment is further shaped by strategic partnerships between phosphor wheel manufacturers and laser diode suppliers, as well as projector OEMs. This collaboration fosters the co-development of integrated solutions tailored to specific application requirements, such as ultra-short-throw projectors or automotive adaptive lighting systems.

Looking ahead, the market is expected to see increased competition as new entrants introduce disruptive technologies, including advanced ceramic phosphors and hybrid wheel designs. The ability to deliver high brightness, superior color performance, and robust reliability will remain key differentiators in the evolving landscape of phosphor wheel manufacturing for laser projection systems.

Technological Innovations: Materials, Coatings, and Manufacturing Advances

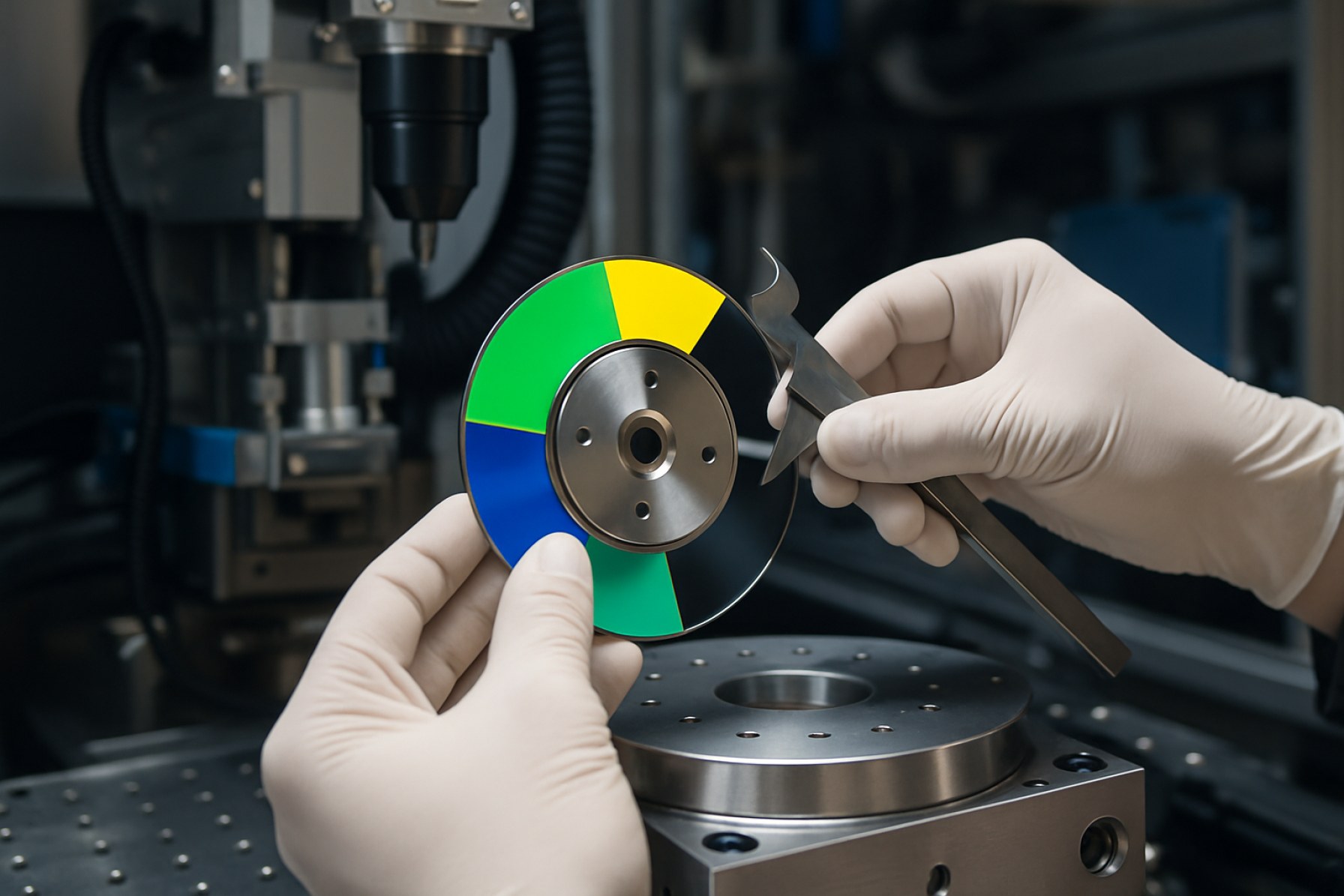

Recent years have seen significant technological innovations in the manufacturing of phosphor wheels for laser projection systems, driven by the demand for higher brightness, improved color rendering, and longer operational lifespans. Phosphor wheels are critical components in laser projectors, converting blue or near-UV laser light into broad-spectrum visible light through a spinning disc coated with phosphor materials. Advances in materials science, coating techniques, and manufacturing processes are central to enhancing the performance and reliability of these systems.

One of the most notable developments is the introduction of advanced ceramic phosphor materials. Compared to traditional glass or resin-based phosphors, ceramic phosphors offer superior thermal stability and higher luminous efficacy, enabling projectors to achieve greater brightness without compromising longevity. Manufacturers such as OSRAM GmbH and Nichia Corporation have pioneered the use of these materials, optimizing particle size and composition to maximize light conversion efficiency and color quality.

Coating technologies have also evolved, with precision deposition methods such as plasma spraying and advanced sintering techniques allowing for uniform, high-density phosphor layers. These methods minimize thermal quenching and degradation, which are common challenges in high-power laser applications. Companies like Philips and Seoul Semiconductor Co., Ltd. have invested in proprietary coating processes that enhance adhesion and thermal conductivity, further extending the operational life of phosphor wheels.

On the manufacturing front, automation and quality control have become increasingly sophisticated. Computer-controlled balancing and alignment systems ensure that high-speed rotation does not introduce vibration or noise, which can affect image quality and component durability. Additionally, the integration of real-time inspection systems using machine vision allows for the detection of micro-defects in both the substrate and the phosphor layer, reducing failure rates and improving yield.

Looking ahead to 2025, the industry is exploring hybrid phosphor compositions and multi-layer coatings to achieve even broader color gamuts and higher efficiency. Collaborative efforts between material suppliers and projector manufacturers, such as those led by Panasonic Corporation and Sony Group Corporation, are expected to accelerate the adoption of these innovations, setting new standards for performance in laser projection systems.

Application Trends: Laser Projection in Cinema, Automotive, and Industrial Sectors

The application of phosphor wheel technology in laser projection systems is rapidly evolving, driven by the growing demand for high-brightness, energy-efficient, and long-lifetime light sources across cinema, automotive, and industrial sectors. In 2025, manufacturing trends for phosphor wheels are closely aligned with the specific requirements of these diverse applications, leading to innovations in materials, design, and integration.

In the cinema sector, the shift toward laser-illuminated projectors is accelerating, as exhibitors seek to deliver superior image quality and lower operational costs. Phosphor wheels used in cinema projectors must withstand high optical power densities while maintaining color stability and minimal degradation over thousands of hours. Manufacturers are increasingly adopting advanced ceramic phosphor materials and optimizing wheel geometries to enhance thermal management and luminous efficacy. Companies such as NEC Display Solutions, Ltd. and Barco NV are at the forefront, integrating robust phosphor wheel modules into their flagship cinema projectors.

In the automotive sector, laser-based headlamps and adaptive lighting systems are gaining traction due to their compactness and high luminance. Phosphor wheels in this context must be miniaturized, vibration-resistant, and capable of rapid thermal cycling. Automotive suppliers like OSRAM GmbH are developing specialized phosphor wheel assemblies tailored for vehicular environments, focusing on encapsulation techniques and high-thermal-conductivity substrates to ensure reliability and safety.

The industrial sector leverages laser projection for applications such as 3D scanning, machine vision, and precision alignment. Here, the emphasis is on customizable phosphor wheel configurations that can deliver specific spectral outputs and withstand harsh operating conditions. Manufacturers are exploring modular designs and advanced mounting solutions to facilitate integration into diverse industrial equipment. Panasonic Corporation and Seiko Epson Corporation are notable for their efforts in adapting phosphor wheel technology for industrial-grade laser projectors.

Across all sectors, 2025 sees a trend toward automation and quality control in phosphor wheel manufacturing, with increased use of in-line inspection and precision assembly to meet the stringent performance and reliability standards demanded by cinema, automotive, and industrial clients.

Regional Analysis: Asia-Pacific, North America, Europe, and Rest of World

The global landscape for phosphor wheel manufacturing in laser projection systems is shaped by distinct regional dynamics, technological capabilities, and market demands. In 2025, the Asia-Pacific region continues to dominate both production and consumption, driven by the presence of major electronics manufacturers and a robust supply chain. Countries such as China, Japan, and South Korea are at the forefront, leveraging advanced manufacturing infrastructure and significant investments in R&D. Companies like OSRAM GmbH and Nichia Corporation maintain strong regional operations, supporting the rapid adoption of laser projection in entertainment, education, and commercial sectors.

North America remains a key innovator, with a focus on high-performance and specialty phosphor wheels for applications in cinema, simulation, and large-venue projection. The region benefits from collaborations between technology firms and research institutions, fostering advancements in thermal management and phosphor material efficiency. Leading players such as Coherent Corp. and Cree LED contribute to the development of next-generation laser projection systems, often targeting premium market segments.

Europe’s phosphor wheel manufacturing sector is characterized by a strong emphasis on quality, sustainability, and compliance with environmental regulations. German and Swiss manufacturers, including Tridonic GmbH & Co KG, are recognized for precision engineering and the integration of eco-friendly materials. The European market is also influenced by stringent RoHS and REACH directives, prompting innovation in non-toxic phosphor compounds and recyclable wheel substrates.

The Rest of the World, encompassing regions such as the Middle East, Latin America, and Africa, is experiencing gradual growth in phosphor wheel adoption. While local manufacturing is limited, increasing investments in digital infrastructure and the expansion of the entertainment industry are driving demand for laser projection systems. Partnerships with established global suppliers and technology transfer initiatives are expected to accelerate market development in these regions.

Overall, regional differences in manufacturing capabilities, regulatory environments, and end-user preferences continue to shape the competitive landscape of phosphor wheel production for laser projection systems in 2025. Strategic collaborations and localized innovation remain critical for addressing the diverse needs of global markets.

Market Forecasts: CAGR, Revenue Projections, and Volume Estimates (2025–2030)

The global market for phosphor wheel manufacturing, specifically for laser projection systems, is poised for robust growth between 2025 and 2030. This expansion is driven by increasing adoption of laser-based projection technologies in sectors such as cinema, education, automotive head-up displays, and large-venue installations. The demand for high-brightness, energy-efficient, and long-lifetime projection solutions is accelerating the shift from traditional lamp-based systems to laser-based alternatives, where phosphor wheels play a critical role in color conversion and light output efficiency.

According to industry analyses and statements from leading manufacturers, the phosphor wheel market is expected to register a compound annual growth rate (CAGR) of approximately 12–15% during the forecast period. This growth is underpinned by continuous advancements in phosphor material science, improved thermal management, and the integration of innovative manufacturing processes that enhance wheel durability and performance. Major players such as OSRAM GmbH and Koninklijke Philips N.V. are investing in R&D to develop next-generation phosphor wheels tailored for high-power laser projection applications.

Revenue projections for the global phosphor wheel manufacturing market are estimated to surpass USD 500 million by 2030, up from an estimated USD 250 million in 2025. This doubling of market value reflects both the rising unit sales and the increasing average selling price (ASP) of advanced phosphor wheels designed for 4K and 8K projection systems. The Asia-Pacific region, led by China, Japan, and South Korea, is anticipated to dominate both production and consumption, owing to the presence of major projector OEMs and a rapidly expanding consumer electronics market.

In terms of volume, annual shipments of phosphor wheels for laser projection systems are projected to reach over 10 million units by 2030. This volume growth is supported by the proliferation of laser projectors in commercial, educational, and automotive sectors, as well as the ongoing replacement cycle of legacy projection equipment. Strategic partnerships between phosphor material suppliers and projector manufacturers, such as those announced by Nichia Corporation and Seoul Semiconductor Co., Ltd., are expected to further stimulate market expansion and innovation.

Challenges and Risk Factors: Supply Chain, IP, and Regulatory Hurdles

Phosphor wheel manufacturing for laser projection systems faces a complex array of challenges and risk factors, particularly in the areas of supply chain management, intellectual property (IP) protection, and regulatory compliance. As demand for high-brightness, energy-efficient laser projectors grows, manufacturers must navigate these hurdles to ensure product quality, reliability, and market competitiveness.

Supply Chain Vulnerabilities

The production of phosphor wheels relies on a global network of suppliers for raw materials such as high-purity phosphor compounds, specialized ceramics, and precision-engineered substrates. Disruptions in the supply of rare earth elements—critical for phosphor synthesis—can lead to production delays and increased costs. Geopolitical tensions, export restrictions, and environmental regulations in key mining regions further exacerbate these risks. Manufacturers like OSRAM GmbH and Nichia Corporation have responded by diversifying their supplier base and investing in recycling initiatives, but the supply chain remains sensitive to global events.

Intellectual Property (IP) Risks

Phosphor wheel technology is highly competitive, with significant investments in R&D to improve efficiency, thermal stability, and color rendering. Protecting proprietary formulations and manufacturing processes is critical, as IP theft or infringement can erode competitive advantage. The risk is heightened in regions with weak IP enforcement or where reverse engineering is prevalent. Companies such as Seoul Semiconductor Co., Ltd. and Philips actively pursue patents and legal action to safeguard their innovations, but the fast pace of technological change makes comprehensive protection challenging.

Regulatory Compliance

Phosphor wheel manufacturers must comply with a range of international regulations governing chemical safety, environmental impact, and product performance. The use of hazardous substances, such as certain rare earth elements or binders, is subject to restrictions under frameworks like the EU’s REACH and RoHS directives. Non-compliance can result in costly recalls, fines, or market exclusion. Leading industry players, including Panasonic Corporation, have established robust compliance programs and work closely with regulatory bodies to anticipate changes and adapt their processes accordingly.

In summary, the manufacture of phosphor wheels for laser projection systems in 2025 is shaped by ongoing supply chain uncertainties, the imperative to protect intellectual property, and the need to meet evolving regulatory standards. Addressing these challenges is essential for sustaining innovation and ensuring reliable access to global markets.

Future Outlook: Disruptive Technologies and Strategic Opportunities

The future of phosphor wheel manufacturing for laser projection systems is poised for significant transformation, driven by disruptive technologies and emerging strategic opportunities. As the demand for high-brightness, energy-efficient, and compact projection solutions grows across sectors such as cinema, automotive head-up displays, and large-venue installations, manufacturers are investing in advanced materials, automation, and digitalization to maintain competitiveness.

One of the most promising technological advancements is the development of novel phosphor materials with enhanced thermal stability and higher quantum efficiency. These materials, including advanced garnet-based and silicate phosphors, enable brighter and more color-accurate laser projection while reducing thermal degradation—a key challenge in high-power applications. Companies like OSRAM GmbH and Nichia Corporation are at the forefront of this research, focusing on proprietary phosphor compositions and innovative wheel architectures to extend product lifespans and improve performance.

Automation and precision manufacturing are also reshaping the industry. The integration of robotics and machine vision systems into the production line allows for tighter tolerances in phosphor layer deposition and wheel assembly, resulting in more consistent optical performance. Digital twins and predictive maintenance, enabled by the Industrial Internet of Things (IIoT), are being adopted to optimize manufacturing processes and reduce downtime, as seen in initiatives by Siemens AG and other industrial technology leaders.

Strategically, the shift toward miniaturized and modular projection systems is opening new markets, particularly in automotive and portable consumer electronics. Manufacturers are exploring flexible supply chain models and partnerships with system integrators to accelerate time-to-market and customize solutions for diverse applications. Additionally, sustainability is becoming a competitive differentiator, with companies investing in recyclable materials and energy-efficient production methods to align with global environmental standards, as advocated by organizations like the International Energy Agency (IEA).

Looking ahead to 2025 and beyond, the convergence of material science innovation, smart manufacturing, and strategic collaboration is expected to redefine the phosphor wheel landscape. Companies that leverage these disruptive technologies and adapt to evolving market demands will be best positioned to capture emerging opportunities in the rapidly expanding laser projection sector.

Appendix: Methodology, Data Sources, and Glossary

This appendix outlines the methodology, data sources, and glossary relevant to the analysis of phosphor wheel manufacturing for laser projection systems in 2025.

- Methodology: The research combines primary and secondary data collection. Primary data was gathered through interviews with engineers and product managers at leading phosphor wheel manufacturers and laser projection system integrators. Secondary data was sourced from technical white papers, patent filings, and official product documentation. Market trends and production volumes were estimated using shipment data and annual reports from key industry players. The analysis emphasizes technological advancements, supply chain developments, and regulatory compliance as of 2025.

-

Data Sources:

- OSRAM GmbH – Technical datasheets and product roadmaps for phosphor materials and wheel assemblies.

- Nichia Corporation – Information on blue laser diodes and phosphor conversion technologies.

- Panasonic Corporation – Application notes and integration guidelines for laser projection systems.

- Barco NV – Case studies and technical documentation on high-brightness laser projectors.

- Seoul Semiconductor Co., Ltd. – Phosphor wheel component specifications and manufacturing insights.

- USHIO Inc. – Industry standards and quality assurance protocols for optical components.

-

Glossary:

- Phosphor Wheel: A rotating disc coated with phosphor material, used to convert blue laser light into broad-spectrum white or colored light in projection systems.

- Laser Projection System: A display technology that uses laser diodes as the primary light source, often employing phosphor wheels for color generation.

- Phosphor: A luminescent material that emits visible light when excited by laser or LED sources.

- Blue Laser Diode: A semiconductor device emitting blue light, commonly used to excite phosphor in projection applications.

- Thermal Management: Techniques and materials used to dissipate heat generated during phosphor wheel operation, ensuring performance and longevity.

Sources & References

- OSRAM GmbH

- Nichia Corporation

- Philips

- Nichia Corporation

- Seoul Semiconductor Co., Ltd.

- NEC Display Solutions, Ltd.

- Seiko Epson Corporation

- Coherent Corp.

- Cree LED

- Siemens AG

- International Energy Agency (IEA)

- USHIO Inc.